Hydrogel dressings, which accelerate and facilitate the healing of burns and wounds, are made at the Institute of Chemistry and Chemical Technologies, Lviv Polytechnic. Chemists have been working on the idea of hydrogel healing materials for ten years and have been improving hydrogel dressings for two years. The beginning of the war and the need for such remedies accelerated the transition of research into a practical format.

― We are still working on the development of this topic, ideas on forms of application and properties, depending on the type of damage. Our hydrogel dressings can be filled with a variety of treatments, such as painkillers, antiseptics, hemostatic and healing. They have a prolonged effect and are anti-allergenic, as well as do not require frequent dressings. These remedies belong to the class of wet wound healing, which is much more effective than dry, – said Roman Nebesnyi, head of Research and Development Department.

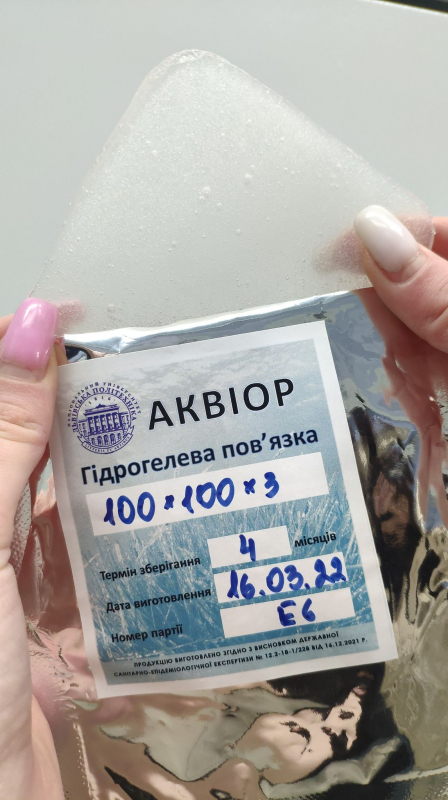

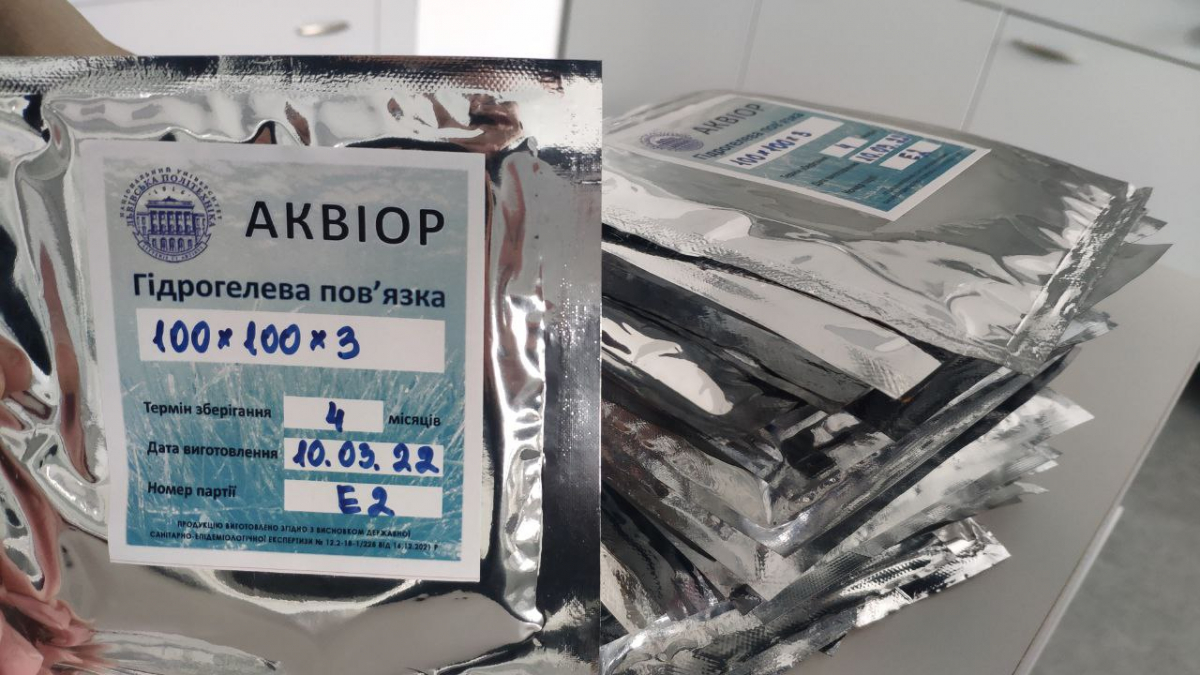

Scientists began to establish the technological process for the manufacture of bandages on February 25, and on March 8 they released the first industrial batches.

― I contacted the volunteer doctors, with whom I have been in contact since 2014, and they confirmed that there will be a great need for these medical supplies. Such bandages are brought from Europe. However, it is quite expensive. For example, imported bandages cost approximately 200 hryvnias a piece, and the cost of ours is several times lower, depending on the size and purpose. At present, all manufactured hydrogel bandages are transferred to clinics free of charge, as the cost is significantly reduced due to the fact that a number of components were delivered to us by volunteers, and our work is a social contribution, – explained Roman Nebesnyi.

He also stressed that the market for hydrogel bandages in Ukraine has not been formed yet.

― If in the world (Western Europe, North America, etc.) the use of hydrogel bandages has long been widely used and doctors understand what their benefits, here these bandages mostly come with humanitarian aid and not all doctors are familiar with their practical application and benefits. For example, the bandages we produce have healing properties, they are made from natural raw materials, and do not cause allergic reactions, do not irritate. In addition, there is no problem with the disposal of used dressings. It is clear that this is not a priority in the conditions of war, but we hope that we will win as soon as possible and that it will be relevant for use in peacetime, including abroad.

In the middle of last year, chemists at Lviv Polytechnic received basic funding from the Ministry of Education and Science: by the decision of the Scientific and Technical Council, a significant part of the funds was spent on designing and building a device for the production of these bandages. The project started in early July. And in half a year the scientific groups of the Department of Organic Chemistry and RL-40, with the active assistance of economic services of the University, managed to design and install a technological line, as well as to obtain basic permits.

― We planned in advance during this year to launch and adjust the technological process, and had to speed up all the preparatory work. So, without waiting for further funding from the state, the staff of the Department of Organic Chemistry in two weeks set the device sufficient to produce the first batch of hydrogel medical dressings. Today we already produce up to 400-500 pieces daily. The technological cycle requires continuous work. In order to optimize the processes as much as possible, we actively consult with manufacturers with extensive experience – with technical directors and chief engineers of specialized enterprises. For us, their advice is very valuable, because we plan to switch to the production of 1000-1500 pieces per day. Installation allows to provide high productivity. But the stages of preparation of raw materials or synthesis of individual components require optimization and greater capacity, because the manufacture of hydrogel dressings is an innovative high-tech complex process that has many stages that require time and extra effort, – said Roman Nebesnyi.

In addition to the internal resources of the Polytechnic Research Department, ROSHEN Confectionery Corporation, a pharmaceutical company from Poland, the Institute of Geology and Geochemistry of Combustible Minerals of the National Academy of Sciences of Ukraine, Institute of Animal Biology NAAS and Lviv City Council provide on a volunteer basis significant material and technical support for operation and optimization of technological process.

The first batches of bandages Polytechnicians have already sent to medical institutions in Kyiv, Lviv, Popasna, and Pisky district. It is important for scientists to receive prompt feedback from physicians and, according to their requests, to adjust the characteristics of these dressings, including size, thickness, morphology and to put appropriate drugs at the stage of production of the dressing itself.

This technology has already outgrown laboratory samples and is currently operated in semi-industrial mode. In the future, it is planned to look for an investor who will be able to develop a full-fledged industrial production to meet the high demand for hydrogel medical dressings in Ukraine.