The peculiarity of innovative developments is their compliance with the needs of society and the state, so recently the priority have been given to science-based solutions in the field of defense and security of citizens. One of these developments is insulating fire resistant glass, which have recently been widely used in various fields. Scientists from Lviv Polytechnic National University also drew attention to it, proposing to use a special hydrogel composition in insulating fire resistant glass and presenting the technology for its manufacture as part of the project «Development of a Hydrogel Composition for Insulating Fire-Resistant Glass and Technology for its Manufacture», which received grant support from the National Research Foundation of Ukraine.

Insulated glazing with fire-resistant properties is used in buildings that are required to meet a certain level of fire resistance in accordance with building codes and standards. At the same time, the use of such glass allows for natural light and visibility in institutions with a large number of people. These include healthcare, education, catering, hotel and leisure complexes, shopping and entertainment centers, office buildings, industrial buildings, warehouses, and airports.

Domestic science is also focused on improving the efficiency of recovery and reconstruction processes in Ukraine during the war and post-war periods, so the use of insulating fire resistant glass remains relevant in the construction of residential buildings as well. Gradually, it has also become a requirement for a number of construction companies that provide housing for Ukrainians in different regions, both in high-rise buildings and private homes. The demand for its use has increased not only in accordance with state building codes, but also to further improve the level of safety in buildings where ordinary residents live. Such requests allowed the developers to pay additional attention to the testing of non-linear insulated glazing and offer a diverse colour palette of fire resistant glass to meet customer requests and find ways to implement various design solutions.

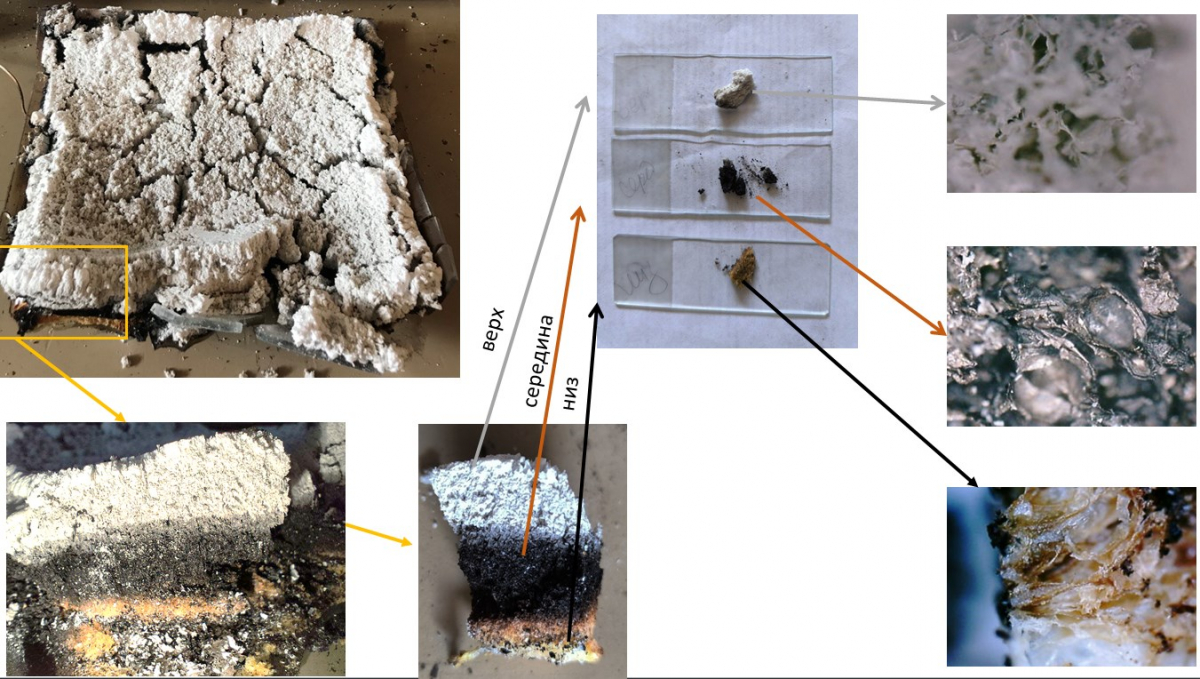

The technology proposed by the research team of Serhii Varvarenko, Professor of Organic Chemistry at the Institute of Chemistry and Chemical Technologies, Lviv Polytechnic, is available for implementation by most companies that manufacture special-purpose insulated glazing and can be a favourable opportunity to expand their product range in a short time and at low financial cost. The technology is based on the production of a liquid filling composition that fills the space between glass window panes. After sealing and heat treatment of the insulated glazing, a transparent hybrid polymer-mineral hydrogel is formed in the laminated glass. In the case of an emergency, such as a fire, it turns into foam and expands under the influence of high temperature. As soon as the temperature rises to 150-250°C, this layer changes its properties and turns into a porous and opaque protective material, which allows the glass structure to maintain its integrity without holes or through cracks, as well as its thermal insulation ability.

«Manufacturers mostly order such glass abroad, so the emergence of a domestic manufacturer of fire resistant glass is in demand and relevant for both producers and consumers of the product. Setting up production in Ukraine will make it possible to produce such glass in the right quantity, in the right size and in a fairly short time frame. It is also worth considering minimal logistics costs, as all the components for the production of the composition underlying the hydrogel layer are available in Ukraine. This, in turn, significantly reduces the cost of the product and makes it more affordable to use. Tests of research batches of fire resistant glass have demonstrated its advantages and favourable price compared to available analogues», said Serhii Varvarenko, coordinator of the project «Development of a hydrogel composition for insulating fire resistant glass and its manufacturing technology», which is being implemented with the financial support of the National Research Foundation of Ukraine.