List of performed works:

- Development of design documentation and slicing machine for bakery products of different shapes and sizes. Machine consists of two reciprocating saw benches, two conveyors (main conveyor and feed conveyor) that are designed to supply products in the cutting area. The design provides the ability to adjust the slope of the feed conveyor within 5°.

The maximum productivity for long loafs is 800 pcs per hour.

Dimensions of products to be cut are 90×150×370 mm.

Power sources — electric network, three phase 380 V, 50 Hz.

Power consumption 0.95 kW.

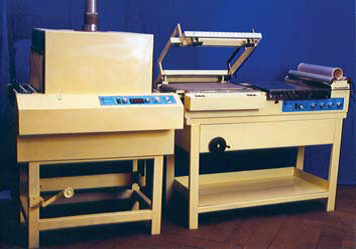

- Development of design documentation and machine for packing of products in a shrink film. Machine can be used for group and single product packaging in various industries. The machine consists of a unit for packing and shrink tunnel. The machine design provides control of the following parameters: conveyor running speed of the unit for packing and shrink tunnel, temperature and duration of the film welding process, shrink tunnel temperature, conveyor vertical displacement of the unit for packing and shrink tunnel.

Machine productivity 240 to 360 pcs per hour.

Power sources — electric network, single phase 220 V, 50 Hz.

Power consumption, operating power 2.5 kW.